Erlab filtration technology traps pollution at the source.

3D printing, also known as additive manufacturing, is widely used in manufacturing, healthcare, education, and other fields due to its low cost, high flexibility, and rapid prototyping capabilities. However, pollutants generated during the printing process can pose serious health risks to operators.

Pollutants & Risks in 3D Printing

The sources and risks of pollutants from 3D printing vary depending on the equipment, materials, and process types.

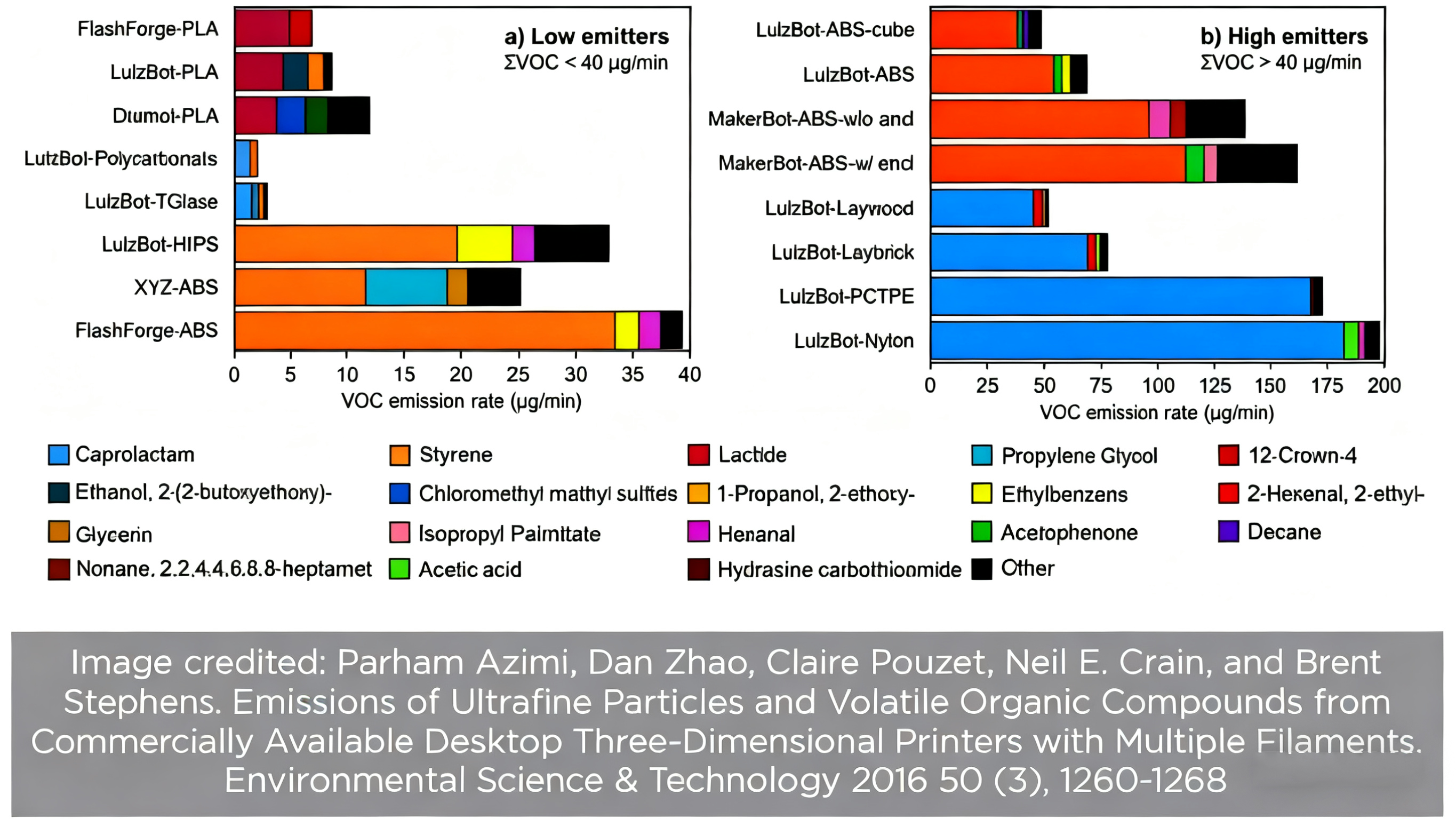

1) FDM (Fused Deposition Modeling): Heating thermoplastic filaments (e.g., ABS, PLA) releases volatile organic compounds (VOCs) and ultrafine plastic particles. ABS can emit styrene and acrylonitrile, which are linked to respiratory illness and neurological damage with long term exposure. PLA is less toxic but can still release trace lactic compounds at high temperatures.

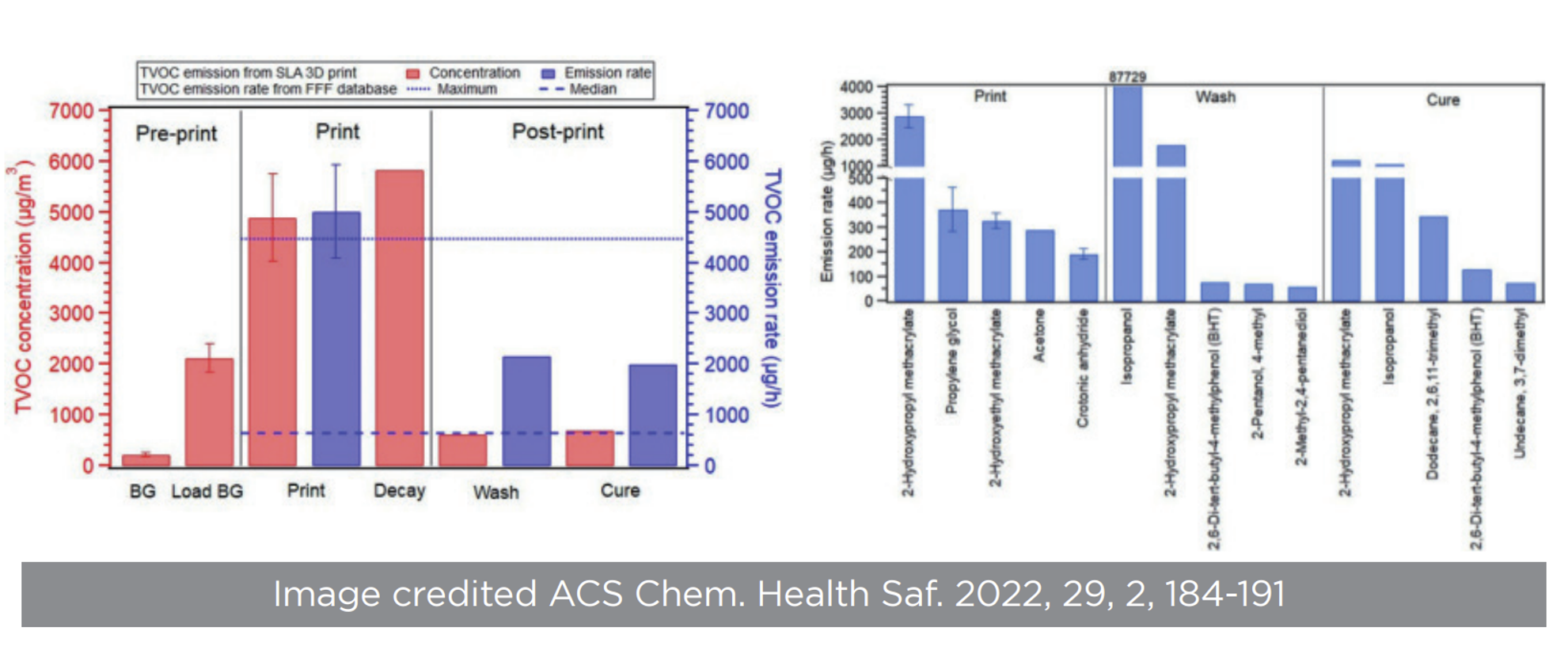

2) SLA (Stereolithography): Photosensitive resins emit VOCs such as esters, alcohols, aldehydes, and aromatics during printing, cleaning, and curing. Many have sensitizing, carcinogenic, or irritant properties, and long-term exposure can cause respiratory irritation, allergies, or chronic toxicity.

Ultrafine Particles (UFPs): The 3D printing process not only releases VOCs but also faces challenges from ultrafine particles (UFPs, also known as nanoparticles, with a size of 1–100 nm). These extremely small particles can be inhaled into the body, enter organs through the bloodstream, and long-term exposure may lead to cardiovascular diseases, respiratory infections, lung cancer, and chronic obstructive pulmo-nary disease

How to effectively reduce and minimize the risks of exposure to 3D printing pollutants.

1) Material & Process Optimization: Use low-VOC, bio-based resins (e.g., PLA), water-based photopolymers, or ISO 10993-certified medical-grade materials. Lowering ABS printing temperatures from 240°C to 220°C can cut VOC emissions by 30–50%. (Journal of Hazardous Materials).

2) Ventilation & Filtration: Improve air circulation in the printing area to ensure pollutants are discharged promptly. At the same time, install equipment equipped with activated carbon and particulate filters to effectively reduce the release of volatile organic compounds.

Erlab Customized Instrument Enclosure

- Adapted to the dimensions of various 3D printers

- Trap pollution at the source, preventing chemical inhalation risks for personnel

- Exhaust Duct not needed, enabling quick installation in the original equipment location

- Flexible modular filtration system suitable for various operations

3) Workplace Safety: Operate in well-ventilated spaces and use appropriate personal protective equipment (PPE)